Page 24 - JSOM Summer 2023

P. 24

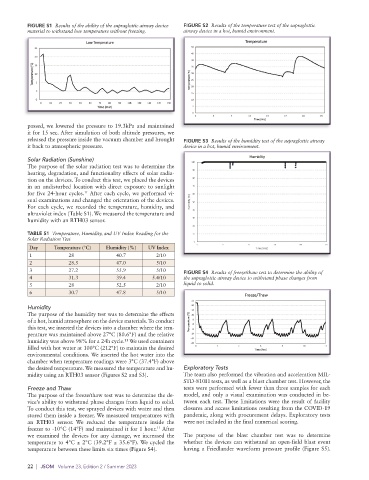

FIGURE S1 Results of the ability of the supraglottic airway device FIGURE S2 Results of the temperature test of the supraglottic

material to withstand low temperature without freezing. airway device in a hot, humid environment.

passed, we lowered the pressure to 19.3kPa and maintained

it for 15 sec. After simulation of both altitude pressures, we

released the pressure inside the vacuum chamber and brought FIGURE S3 Results of the humidity test of the supraglottic airway

it back to atmospheric pressure. device in a hot, humid environment.

Solar Radiation (Sunshine)

The purpose of the solar radiation test was to determine the

heating, degradation, and functionality effects of solar radia-

tion on the devices. To conduct this test, we placed the devices

in an undisturbed location with direct exposure to sunlight

11

for five 24-hour cycles. After each cycle, we performed vi-

sual examinations and changed the orientation of the devices.

For each cycle, we recorded the temperature, humidity, and

ultraviolet index (Table S1). We measured the temperature and

humidity with an RTH03 sensor.

TABLE S1 Temperature, Humidity, and UV Index Reading for the

Solar Radiation Test

Day Temperature (°C) Humidity (%) UV Index

1 28 40.7 2/10

2 28.5 47.0 5/10

3 27.2 55.9 5/10

FIGURE S4 Results of freeze/thaw test to determine the ability of

4 31.3 39.4 5.4/10 the supraglottic airway device to withstand phase changes from

5 28 52.5 2/10 liquid to solid.

6 30.7 47.8 5/10

Humidity

The purpose of the humidity test was to determine the effects

of a hot, humid atmosphere on the device materials. To conduct

this test, we inserted the devices into a chamber where the tem-

perature was maintained above 27°C (80.6°F) and the relative

humidity was above 98% for a 24h cycle. We used containers

11

filled with hot water at 100°C (212°F) to maintain the desired

environmental conditions. We inserted the hot water into the

chamber when temperature readings were 3°C (37.4°F) above

the desired temperature. We measured the temperature and hu- Exploratory Tests

midity using an RTH03 sensor (Figures S2 and S3). The team also performed the vibration and acceleration MIL-

STD-810H tests, as well as a blast chamber test. However, the

Freeze and Thaw tests were performed with fewer than three samples for each

The purpose of the freeze/thaw test was to determine the de- model, and only a visual examination was conducted in be-

vice’s ability to withstand phase changes from liquid to solid. tween each test. These limitations were the result of facility

To conduct this test, we sprayed devices with water and then closures and access limitations resulting from the COVID-19

stored them inside a freezer. We measured temperatures with pandemic, along with procurement delays. Exploratory tests

an RTH03 sensor. We reduced the temperature inside the were not included in the final numerical scoring.

11

freezer to -10°C (14°F) and maintained it for 1 hour. After

we examined the devices for any damage, we increased the The purpose of the blast chamber test was to determine

temperature to 4°C ± 2°C (39.2°F ± 35.6°F). We cycled the whether the devices can withstand an open-field blast event

temperature between these limits six times (Figure S4). having a Friedlander waveform pressure profile (Figure S5).

22 | JSOM Volume 23, Edition 2 / Summer 2023